Seven Dreamers is a new shaft company launched early 2014, while new the company has a long standing history in composites dating back for over half a century. In 1955 Minamoto Takeishi Watanabe came across a material that left him intrigued with all it’s possibilities, he decided to single handedly study composites and after 2 years of research in 1957 established his very first composite molding plant in Shibuya, Tokyo and thus began the company Super Resin Inc. Click Read More to Continue…

Originally it started off with glass fiber composites then a year later in 1971 Super Resin took the global lead in molding carbon fiber reinforced plastics (CFRP). For those of you who are new to CFRP it’s basically a composite material made of fibers and resins that has a very high strength to weight ratio that is often used in aerospace, automotive and recently sporting goods. unlike materials like steel or aluminum CFRP has directional strength properties that depend on the design and lay out of the carbon fibers.  By the mid 80’s super resin expanded into Advanced Composite Materials (ACM) establishing their first ACM plant pursuing R&D in the aerospace field and as a result developed a CFRP remote control space (drone) in 1988. Over the next decade Super Resin was the supplier for many materials used in space satellites which would evenutally lead them to join the Hayabusa project in the late 90’s. The Hayabusa project is the first and only unmanned spacecraft to land on an asteroid and return to earth with an asteroid sample.

By the mid 80’s super resin expanded into Advanced Composite Materials (ACM) establishing their first ACM plant pursuing R&D in the aerospace field and as a result developed a CFRP remote control space (drone) in 1988. Over the next decade Super Resin was the supplier for many materials used in space satellites which would evenutally lead them to join the Hayabusa project in the late 90’s. The Hayabusa project is the first and only unmanned spacecraft to land on an asteroid and return to earth with an asteroid sample.

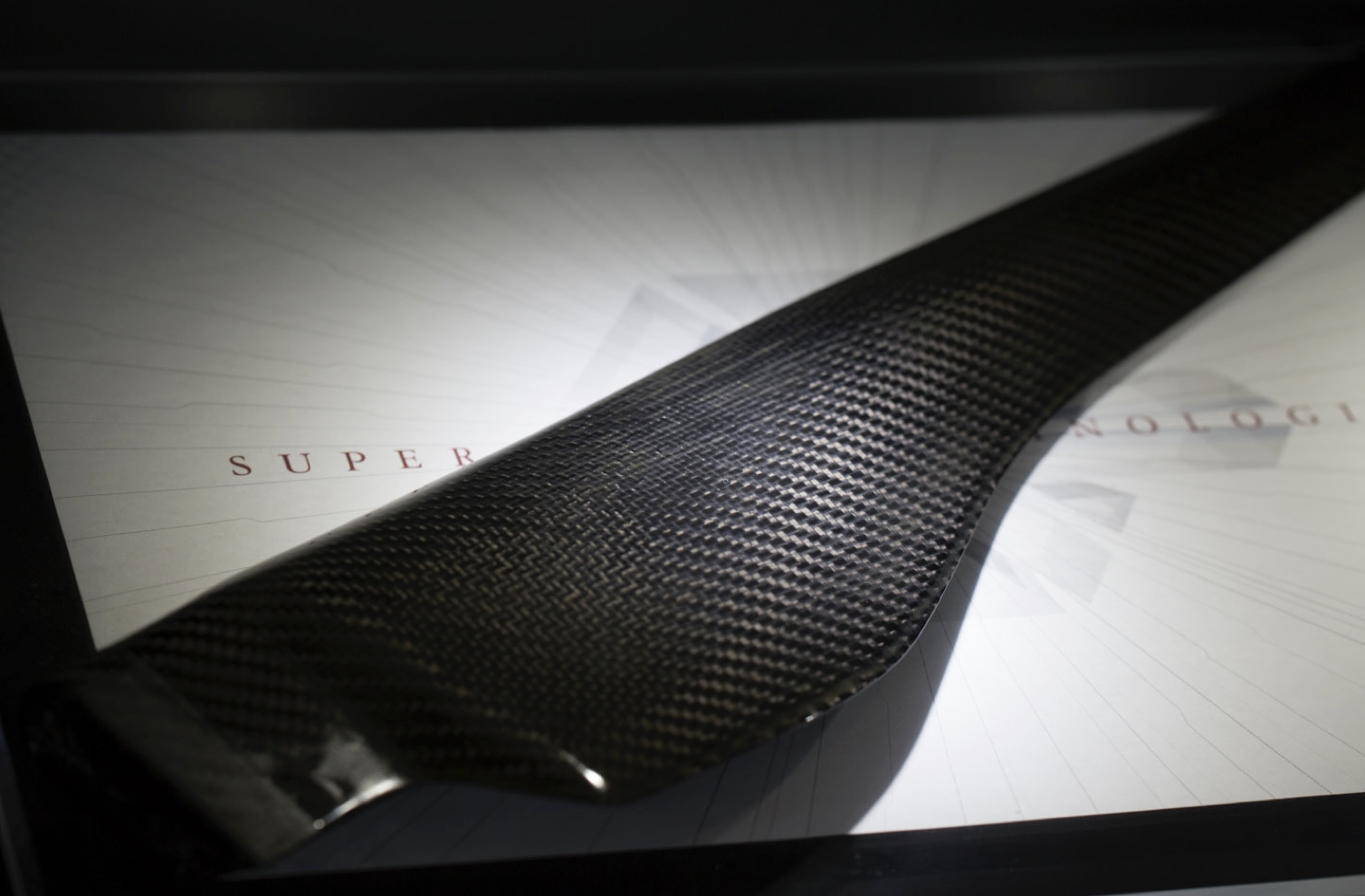

Super Resin materials are found in almost every satellite launched in Japan Today. Are all these advanced materials and technology overkill for a golf shaft? Simply put no it isn’t, already on the market there have been shafts costing upward of $1000 dollars and some based on hype or fancy branding so now finally a shaft arrives that provides and justifies the price with quality, technology, and the consistency our money deserves.

Are all these advanced materials and technology overkill for a golf shaft? Simply put no it isn’t, already on the market there have been shafts costing upward of $1000 dollars and some based on hype or fancy branding so now finally a shaft arrives that provides and justifies the price with quality, technology, and the consistency our money deserves.

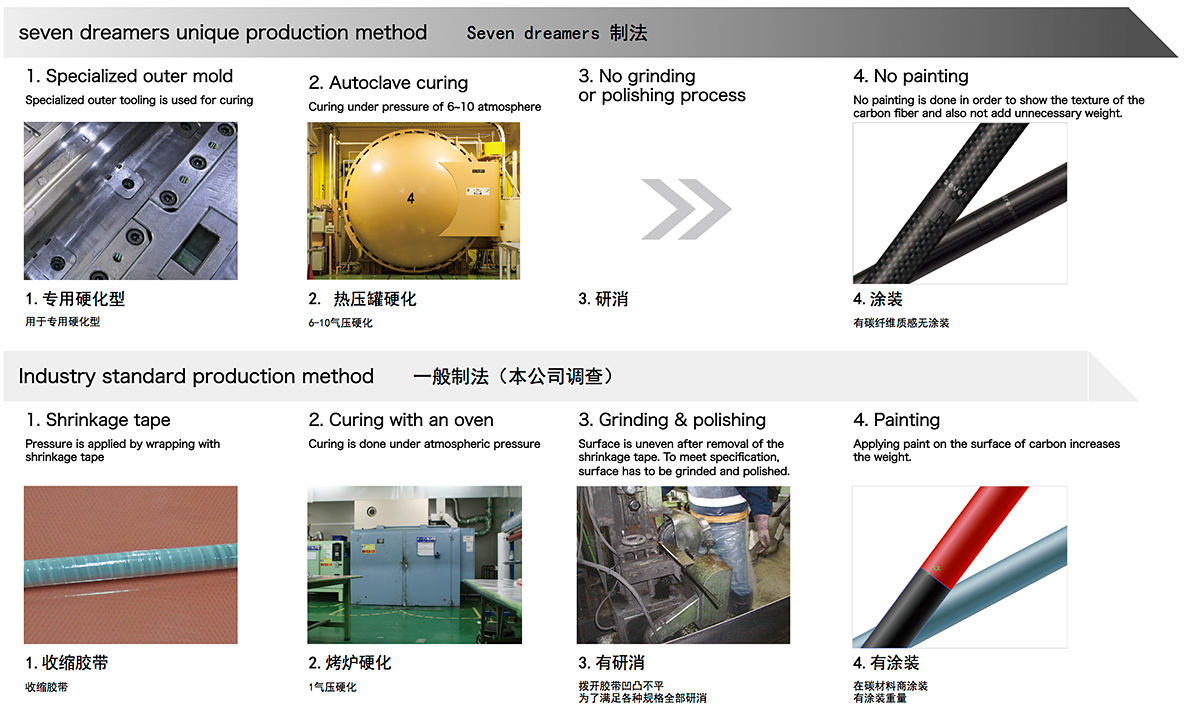

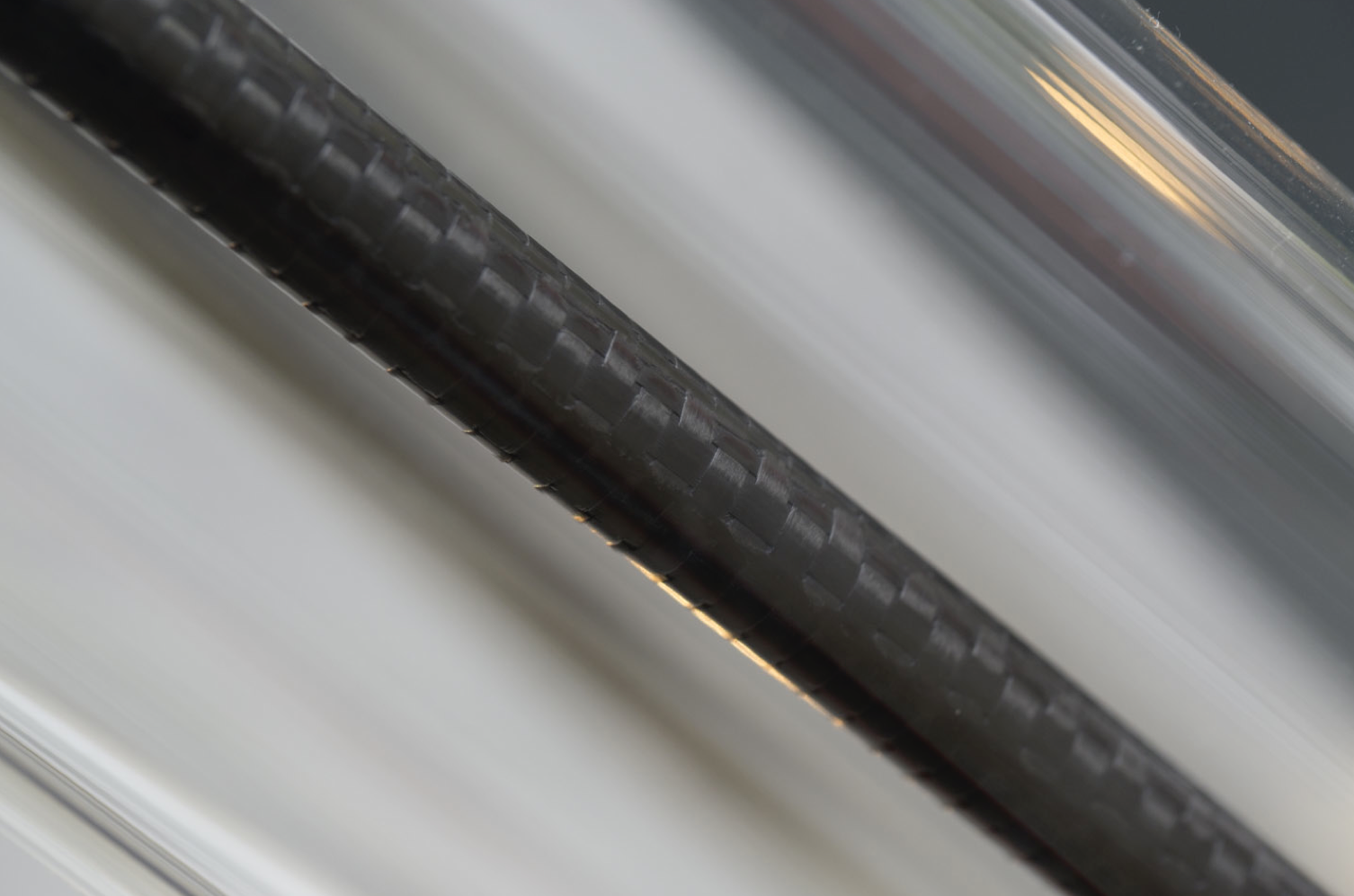

What makes a shaft from Seven Dreamers stand above others? Below we breakdown the difference between Industry standard shaft vs the way Seven Dreamers builds their shafts. In the standard industry process, shafts are made using a normal oven under atmospheric pressure. To apply pressure during processing, the shafts are wrapped with a shrink tape, After the process the tape has to be removed and when removed it leaves an uneven surface.

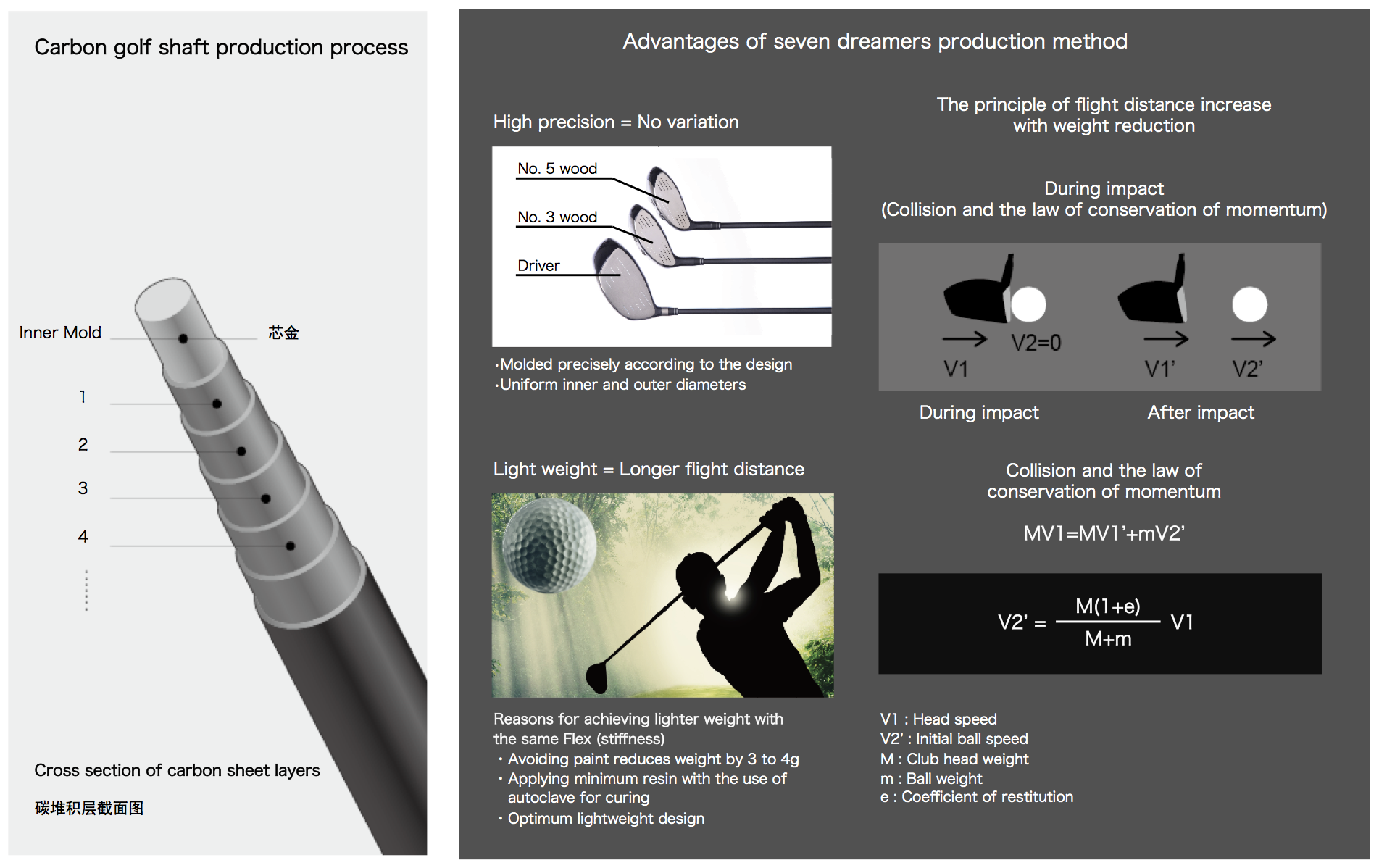

The Seven Dreamers process uses actual inner and outer metal molds while the shafts are processed in an autoclave under pressure, no need to apply shrink tape.

To smooth the uneven surface, the industry standard shaft requires grinding and polishing but the grinding while it smooths out the surface it also damages the individual fibers and that has a major impact on the performance of the shaft, the carbon fiber itself and the design is what gives the shaft its unique strength and stiffness.

The Seven Dreamers shafts are smooth as they come out of the massive autoclave, there is no need to grind and polish and there is also no need to paint either because the shaft is made perfect and true to it’s blueprint with no variables or extra weight from paint. The results are shafts manufactured as they are designed consistent from one shaft to the other.

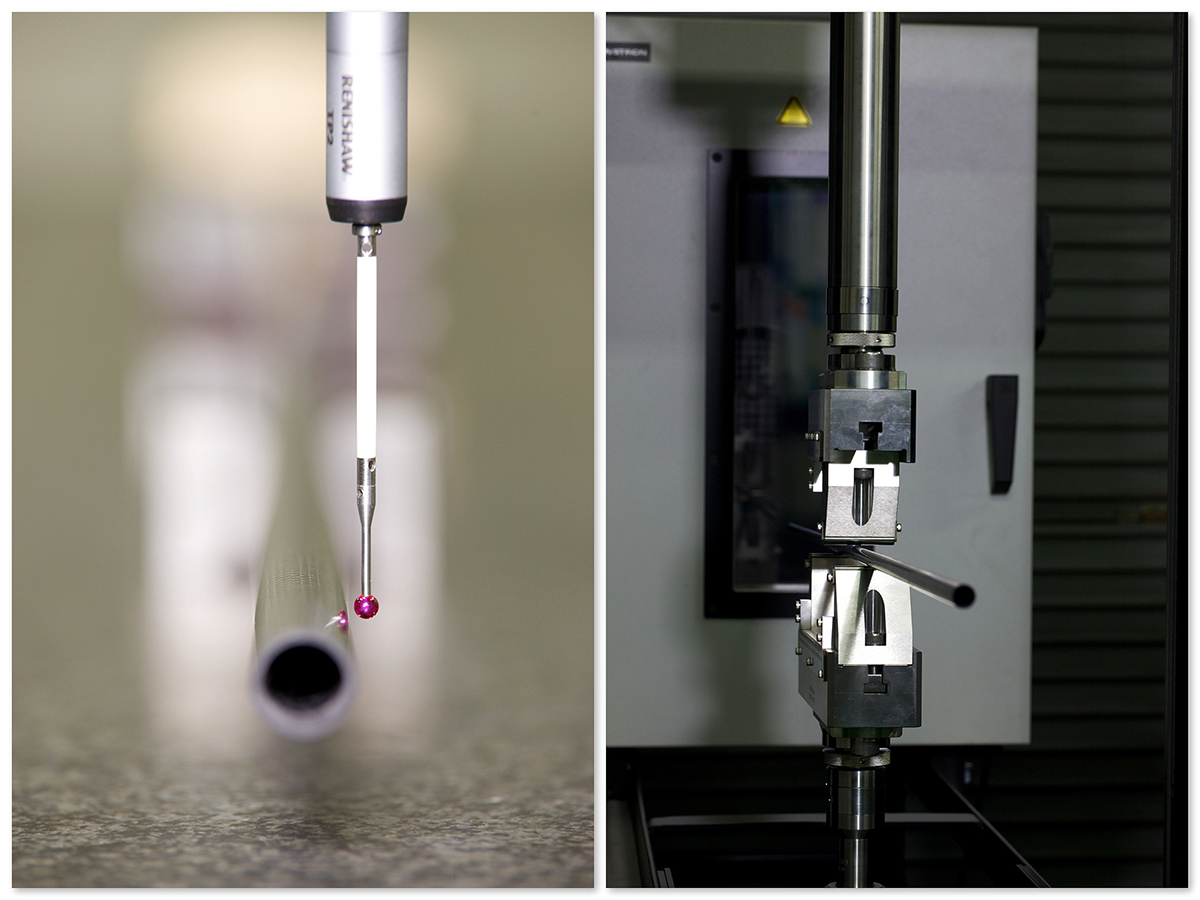

The outer mold keeps the shaft perfectly round while in the autoclave, the result is complete accuracy unlike other shafts. One of the most exciting aspects about working with Seven Dreamers is their scientific approach to total club performance, Seven Dreamers actually takes the customers club head into consideration with their proprietary fitting process during the shaft selection phase.

The outer mold keeps the shaft perfectly round while in the autoclave, the result is complete accuracy unlike other shafts. One of the most exciting aspects about working with Seven Dreamers is their scientific approach to total club performance, Seven Dreamers actually takes the customers club head into consideration with their proprietary fitting process during the shaft selection phase.

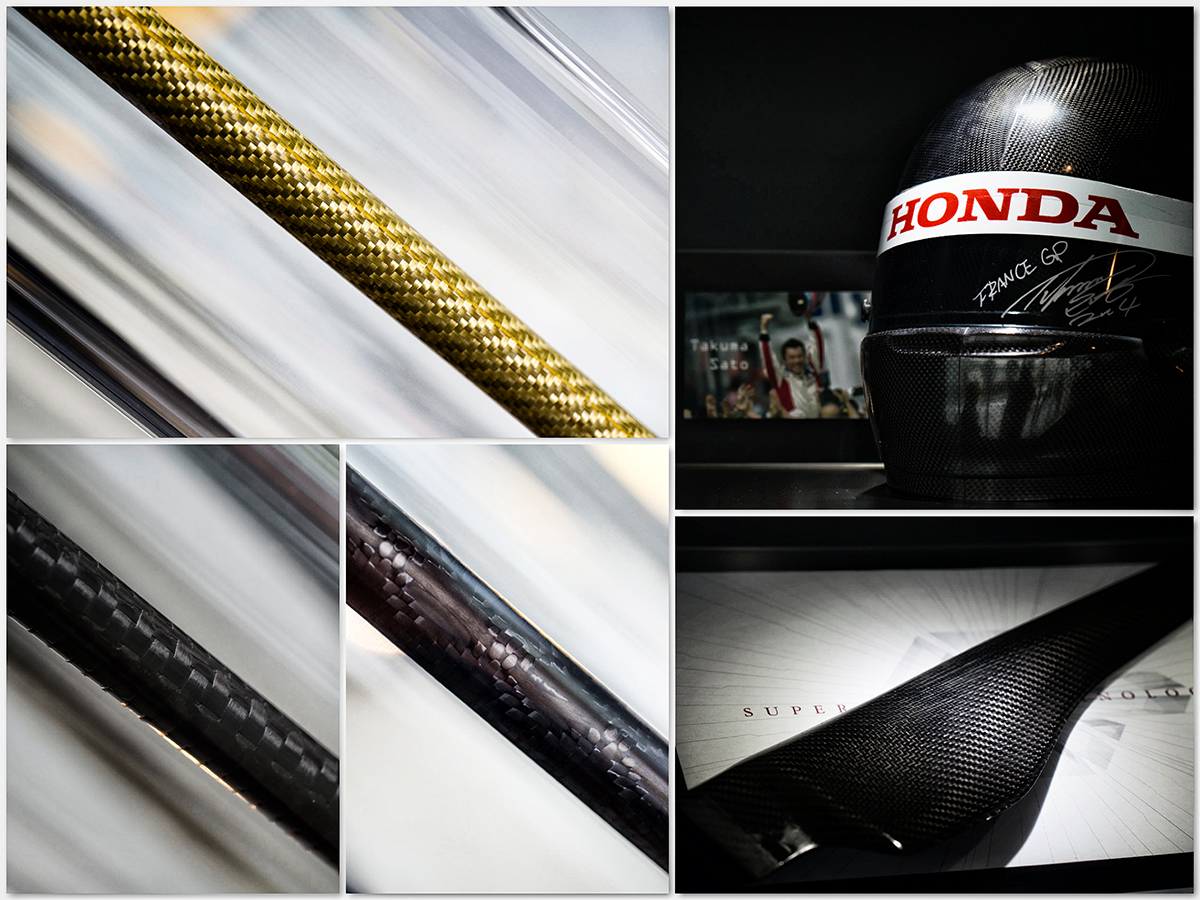

Paint add’s unnecessary weight and covers carbon material inconsistencies, similar to how a plated finish can hide grind defects on an iron or wedge. Seven Dreamers shows it’s bare carbon as a testament to the qualities of material they use.

Seven Dreamers received the a lot of marketing buzz surrounding it’s $120,000 golf shaft, people were thinking what the heck!? but then I began to understand how awesome it really is, this is more than just a shaft it’s something made for you of words best technology, This insanely priced “Premium shaft” uses unique carbon fiber products developed for state-of-the-art satellite applications, the shaft is manufactured with a special invar alloy mold that has low heat expansion and is currently used in the aerospace industry (which actually takes most of the cost of manufacturing the product). Upon completion this top end shaft is encased in a special carbon fiber composite case with the actual super invar mold used to make the product included. Here is the break down, hold your breath this is in U.S dollars:

- Matrix – $1200 – Based on a 16 questions Seven Dreamers fits you into one of 50+ shafts through TSG

- Haute Couture – $1800 – Fully Custom Fit in Japan Studio

- Anniversary – $10,000 – Amazing Gift for an special anniversary in Gold/Silver/Various textile patterns and space materials (not for play)

- Space – $15,000 – A different more rare space use material used in satallites

- Premium – $120,000 – A shaft made for you of insane materials, metal mold, carbon case, full experience in Japan.

TourSpecGolf only sell’s the Matrix series for the simple reason that most of our clients are not able to fly to Japan to be fit for the Haute Couture models. What we can do for anyone visiting Japan is arrange an english speaking fitting and experience.

There are 57 shafts in the Matrix series and after a 16 question fitting using specific questions provided by Seven Dreamers HQ we send that data back and they provide the customer with 3 options to choose from: Standard – Distance – Control shafts, pretty self explanatory, the Standard is a combo of the two.

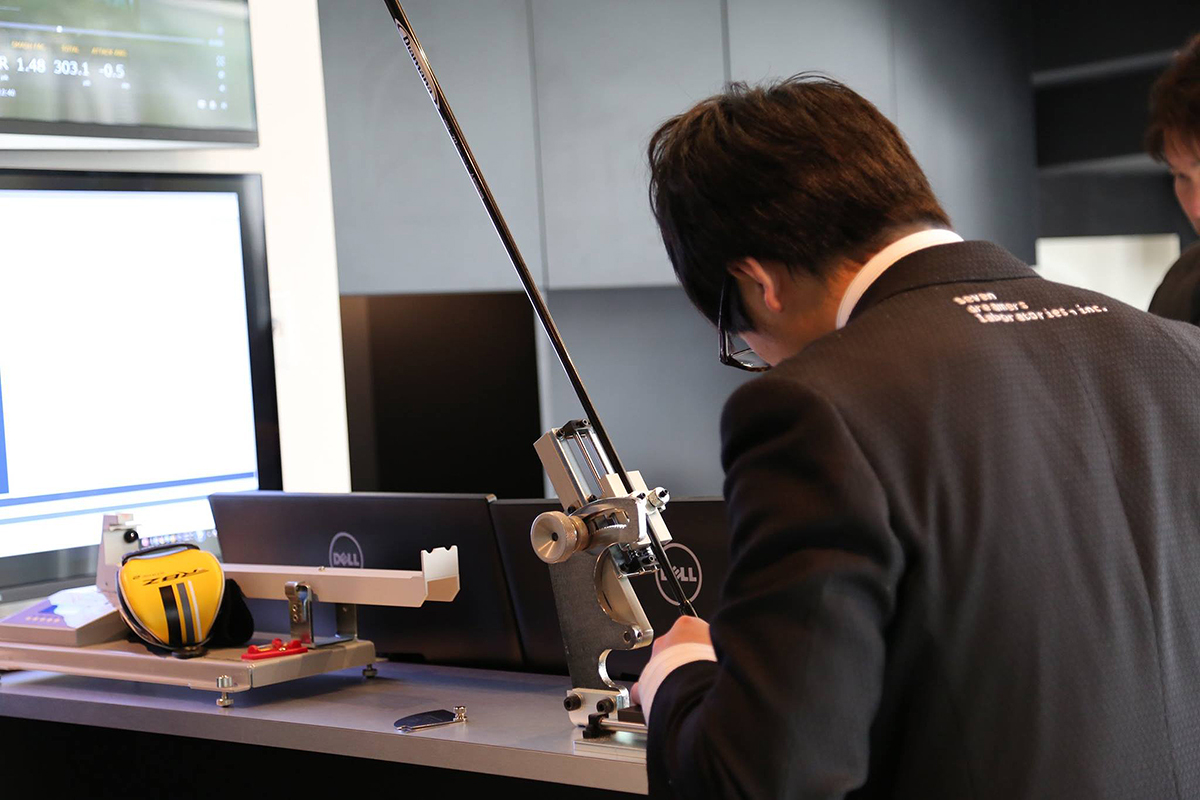

The Haute Couture line requires the customer to visit an actual Seven Dreamers location for a personal fitting, this is a fitting to remember but you will need a translator if you just drop in, so we suggest contacting TSG if you are in the area and we will arrange an english speaker there to help you though the fitting.

Seven Dreamers uses a proprietary software that is combined with the latest Trackman, the fitting is done using Seven Dreamer heads so that they can isolate variables and fit your swing with a shaft, not the head. After your fitting it takes about a week for your data to be processed and the recommendation made, after you select your shaft it is made to order then shipped to you in a stunning box and owners guide.

So what is the best way to experience a Seven Dreamer’s shaft, obviously if you are in Tokyo please contact TSG and we can arrange a fitting in your language, other than that contact TSG if you have serious interest and we can get in touch to go over the 16 question fitting process.

Why give Seven Dreamers a try? well for one it’s easily the most consistent and well made shaft in golf PERIOD! Don’t agree? I challenge any shaft company to prove otherwise. The inner and outer walls are exact with no variation and perhaps even more importantly is they know how to break down each of the 16 sequential questions to provide you with the proper shaft for your swing. The Seven Dreamers shaft’s also have less resin so you get more of the materials that matter most to performance. The philosophy is based on science surrounding the laws governing the conservation of momentum and the coefficient of restitution and show how weight reduction results in increase in club head speed and ball flight.

Initial ball speed comes from the head speed, head weight, ball weight, and C.O.R and it is scientifically proven that a lighter club equals higher initial ball speeds which begs the question how light can one go without hitting it wild? Only with the use of the best carbon materials and designs can you keep shaft deformation down squaring the club face up at impact with such a light weight club. Now that doesn’t mean they only make Light shafts, Seven Dreamers also has some beasts in their line up as well but the principle of increased distance with weight reduction can’t be argued.

So far only a small handful of TSG’ers have these in the bag today. It’s a bit early to tell what the masses will think of them but I applaud Seven Dreamers for pushing the envelope to another level creating a new standard setting the bar high for any shaft company to rival them in the arena of technology and materials. Expect there to be more info about Seven Dreamers and our lucky TSG’rs who have decided to splurge and put one of their in their favorite driver.

So far only a small handful of TSG’ers have these in the bag today. It’s a bit early to tell what the masses will think of them but I applaud Seven Dreamers for pushing the envelope to another level creating a new standard setting the bar high for any shaft company to rival them in the arena of technology and materials. Expect there to be more info about Seven Dreamers and our lucky TSG’rs who have decided to splurge and put one of their in their favorite driver.

If you are interested in purchasing a Matrix series shaft please inquire with [email protected], the process is pretty straight forward, after payment we submit 16 in depth questions for you to fill out, then send it into SD HQ in Tokyo where they will provide 3 suggestions, after choosing the shaft is made to order and delivered directly to you. We do suggest doing this at time of new club purchase from TSG, this allows us to send the custom order spec’d head to Seven Dreamers for the installation and measurements.

Hi,i would like to choose matrix stuff shaft combine with Titleist 917. So how can I get it? Looking forward to your reply.