Some of you may remember the special blog that we did a while back about Syncagraphite who produce Loop shafts. I recently had an opportunity to speak with Syncagraphite’s CEO, Masa Tsujigai in an interview to ask about what sets apart Loop shafts from other shafts in the market. Today we will dive a little deeper into what makes Syncagraphite produces some of the best performing shafts in the industry and how a smaller company can hold it’s own against the big boys of the shaft business. Follow the jump to read on…

“What is unidirectional manufacturing and how specifically is it different than say Fujikura or Mitsubishi?”

Mitsubishi and Fujikura, for example, are mostly using multi-axis Pitch type carbon fiber to manufacture their shafts. They have a tendency to use more epoxy because putting together Pitch type material into a shaft form requires more epoxy.

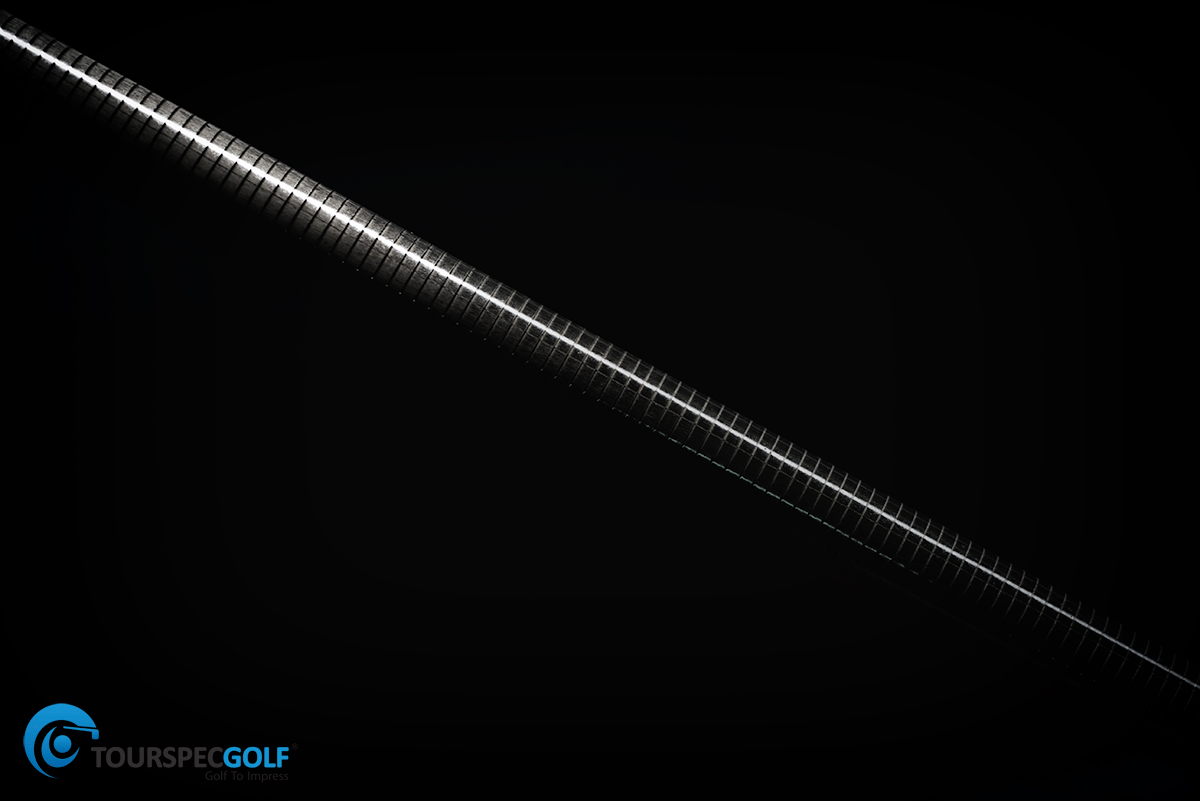

The unidirectional carbon fiber used by Syncagraphite in their Loop shafts are mainly constructed of Pitch type carbon fiber. The fiber laid for unidirectional carbon fiber is one direction. It is the most basic and fundamental form of carbon fiber sheet that is made today.

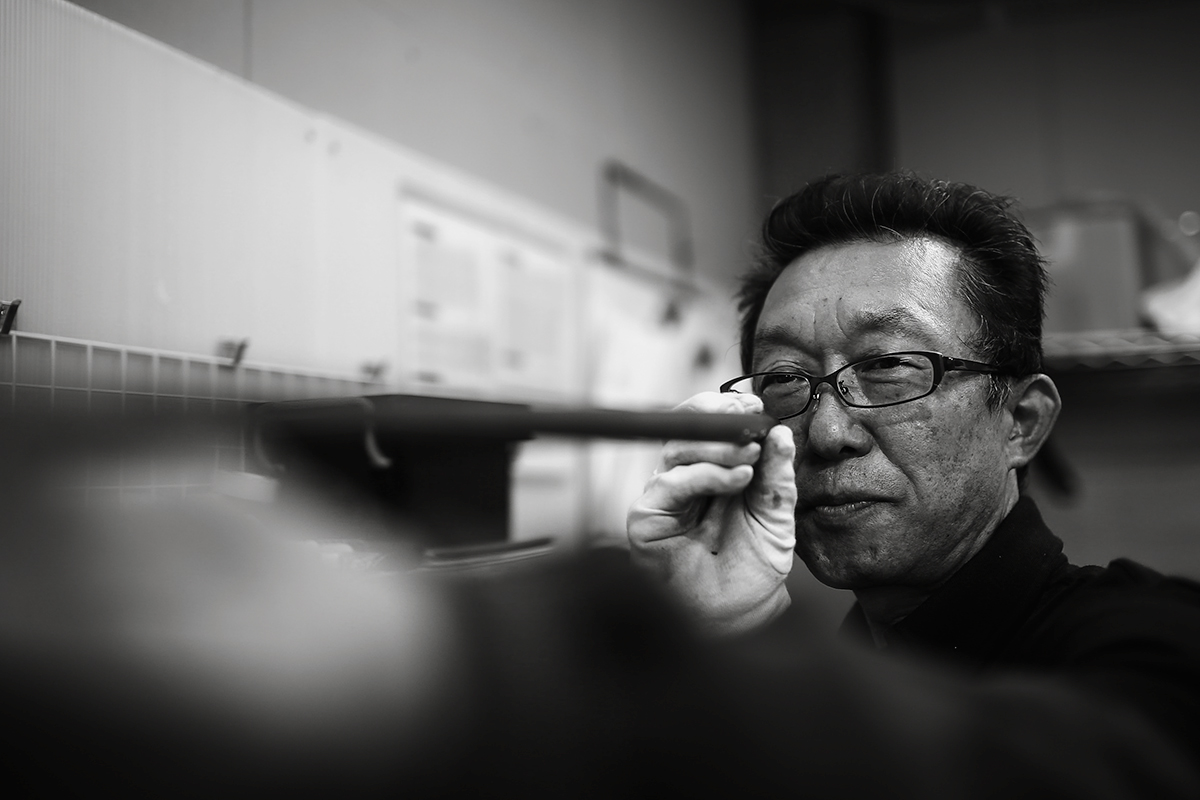

Syncagraphite has 2 highly experienced shaft craftsmen who have been “assembling” shafts using unidirectional carbon fiber sheets for over 40 years.

We’ll use the term “assembling” because when you look at the way they form a shaft, it’s not a simple rolling of large sheets into a shaft. There are many smaller pieces of strategically shaped carbon fiber sheets that are purposefully placed and finally baked into shaft form.

Loop mainly uses unidirectional PAN type carbon fiber to achieve what some may call unique shaft profile and characteristics. They believe that using PAN type material allows them to be much more flexible with their design concepts and be very specific with their shaft profiles. They have now grown their shaft line up to 9 different shafts which they feel can fulfill most player profiles. Loop shafts feature shafts designs that utilize the kick action of the tip section for maximizing distance performance. The degree of the kick will vary by model

One of the benefits of using PAN type unidirectional carbon-fiber technology is that the resulting characteristic of the shaft is more natural and predictable. “Better feel” is oftentimes also called out as being one of the benefits of using PAN type material.

While there are numerous performance and feel benefits of shafts made of PAN type unidirectional material, there are also some challenges that shafts made of pitch type carbon material do not encounter.

Another distinguishing matter with Loop shafts may be the fact that their production yield with the current process is around 60%. Due to their very tight quality control (QC) process and allowable tolerances, 40% of their shafts do not make it through QC. That’s a lot of shafts that do not make it on to the course! However costly it is to maintain their quality, this is one area that Syncagraphite and their manufacturing craftsmen cannot and will not compromise. They take pride in what they deliver out to their clients will always be a top-notch quality that meets their rigorous standards.

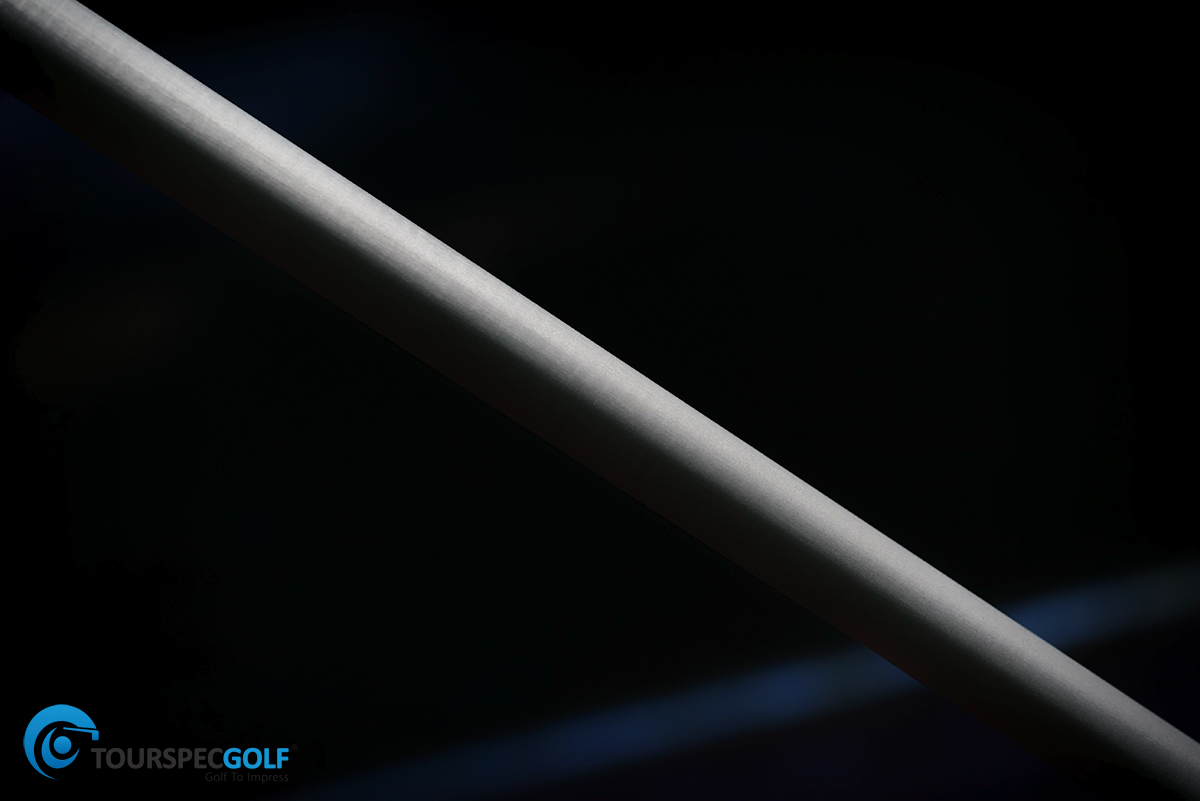

So why the 60% yield? This is ultimately related to the use of Unidirectional PAN type carbon fiber material they use. Once the material is assembled into a shaft form, they are baked to harden and cure the material. During this process, Unidirectional PAN type carbon fiber material can exhibit some level of bowing. This is in fact why many manufacturers have moved away from using these traditional materials. It’s hard to control the bowing. Regardless, Syncagraphite continues to use the highest quality PAN type material supplied by a major Japanese carbon fiber company to produce some of the best feeling golf shafts available today. The advantage of using Unidirectional PAN type material is that you get a very natural feeling shaft where the tip section is designed to move and provide added distance performance. There are so many shafts on the market today that utilizes higher grade pitch type material and multi-axis weaving material like T1100G, MR70 , 80T and 90T carbon etc… but simply put, Syncagraphite believe that many of the high-grade material used today by other shaft companies just produce a shaft that is too stiff for most and really does not do its intended job to be the “engine” of a golf club. With Loop shafts, you can expect the shaft to flex and do its intended job.

While Syncagraphite will maintain their main direction of using PAN type material, as new material and technology that matches their product direction are developed, they will incorporate these new technologies if it makes sense in complementing their products and supports their product direction.

Loop driver shafts now come in 9 different models. Each shafts are designed with a specific player/swinger profile in mind. The below X-Y diagram on the left shows where each of the shafts is positioned relative to each other. Higher up in the graph means a higher trajectory. On the horizontal axis, more left means easier to draw and right means easier to fade.

The diagram on the right-hand side is the shaft profile left-hand side is the butt end and right-hand side is tip end. The numbers indicate the relative stiffness. The yellow dots indicate the approximate bend point.

As for recommendation of which shaft works well with different swing types, and what heads are good matches to the shafts, below is the summary. The matching head are simply examples of what has worked in their fitting in the past, meaning that there are other combinations that may work as well. Tsujigai-san also mentioned that in addition to the JDM boutique brands, recent USDM heads have also been very good and can be combo’d with Loop shafts for good results.

- 100+mph swing speed, aggressive transition, fade hitter: GK ( BALDO420s / TaylorMade )

- 100+mph swing speed, smooth transition, fade hitter: JJ or IP ( JBEAM 535 / PING )

- 100+mph swing speed, aggressive transition, draw hitter: LX ( JBEAM J3 / PING )

- 100+mph swing speed, smooth transition, draw hitter: CL ( BALDO 460 / JBEAM J3 )

- 85 mph swing speeds, aggressive transition, fade hitter: H.D or LT ( THE G / Titleist / PING )

- 85 mph swing speeds, smooth transition, fade hitter: AI ( JBEAM Glorious / TaylorMade )

- 85 mph swing speeds, aggressive transition, draw hitter: BW ( ROMARO / TaylorMade )

- 85 mph swing speeds, smooth transition, draw hitter: Bubble Light ( ROMARO / Callaway )

All Loop shafts are available in the Pro Shop! (Click Below)