Test results are in! For those who have missed it there was a big controversy about Scratch Golf’s advertising claims that spanned across multiple forum’s and blog websites. Here were the claims I made against Scratch Golf last week:

1. It was my opinion that they did not use 1018 carbon steel for their Irons & Wedges

2. Scratch Golf claims Forged by Ishihara-Shoten yet Ishihara-Shoten doesn’t forge golf clubs

3. ( TSG ) wedge was not Ishihara Forged or made of 1018 as we were led to believe

4. Scratch is using Open Model Blanks dispite claiming their products are Original Designs

Let’s get right to it with the Test Results! I sent in 6 sample heads to METL. Metals Engineering and Testing Laboratory based out of Phoenix, Arizona. Here is a short blurb on what they do for their customers…

(Metals Engineering and Testing Laboratory) customer base includes major aerospace and defense contractors, both the fossil and nuclear power utilities, the fastener industry, the automotive industry, insurance companies, attorneys, construction, manufacturers, and metal processors such as heat treaters, coating and plating shops, weld shops, foundries, forge shops, extrusion plants and machine shops. Our metallurgical testing laboratory serves as a valuable resource for a number of smaller companies who use the laboratory for in-depth metallurgical engineering and testing support.

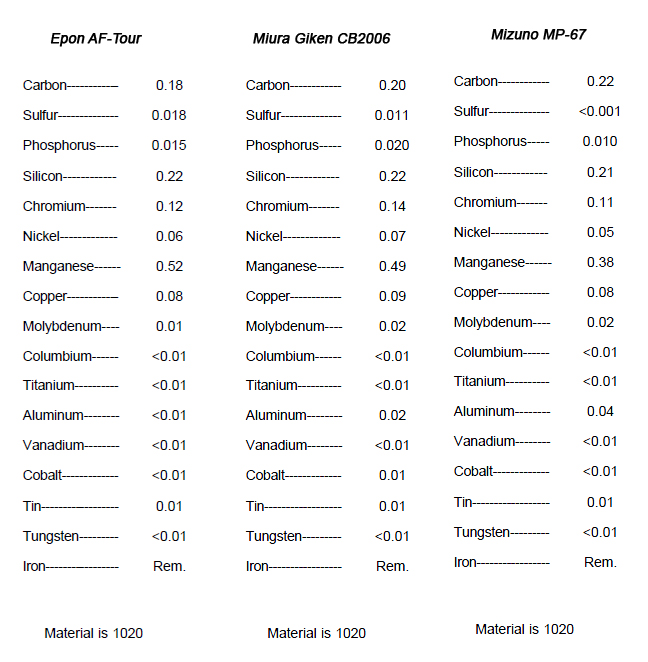

We submitted sample heads from popular brands like Mizuno, Epon, Miura Giken, Geotech and Scratch Golf. Click “Read More” to continue on for the test results…

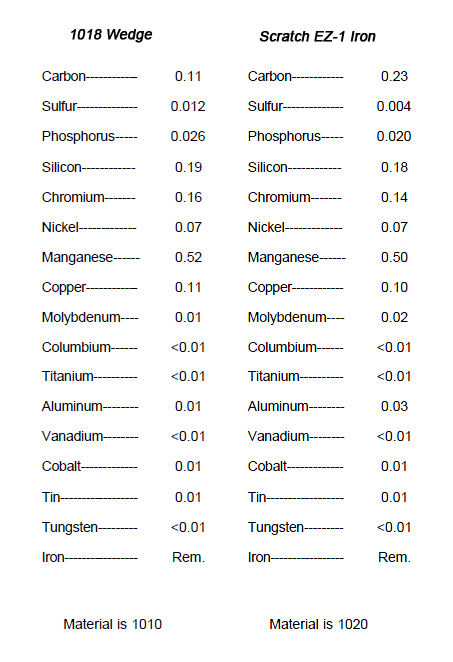

We submitted 2 heads in total from Scratch Golf, one 1018 wedge and one EZ-1 cavity back iron. From Epon we sent in the AF-Tour, Mizuno MP-67, and Miura Giken the CB2006 model.

In regards to testing, heat treatment and plating make no difference at all in the test results as the testing finds the chemical and mineral balance deep inside the head. The above are UNS standards not JIS, the difference between the two is that JIS standards hold tighter tolerance on the minerals and chemicals. The carbon rating is not the only thing to look at, there is a range of other minerals that need to fall into a tolorence allowing METL to come to the conclusion as stated at the bottom of the test.

There is no room for question due to any overlap’s in minerals. If it says 1020 it’s 1020 by UNS Standards. If it says 1010 it’s 1010 by UNS standards.

When cross referencing the UNS results with JIS, The 1020 UNS in the the EZ-1 iron falls near the minimum requirements of JIS S25C. While the UNS rated 1010 doesn’t have the acceptable tolerance to meet JIS standards. By both UNS & JIS standards of the two Scratch Samples sent in none of them are using 1018 steel.

But why that 1010 conclusion on the 1018 wedge? It would have to be an EXTREMELY poor quality piece of metal skipping from 1018 past 1017, 1015, 1012 into the 1010 range. I don’t know if this is a freak wedge but it doesn’t meet any countries standards if it’s supposed to be 1018. It’s 4 carbon metal designations apart from what it was advertised to be. That is surprisingly bad if it was supposed to be 1018 even by China’s metal standards.

In regards to the Mizuno, Miura Giken, and Epon product checkout the chart below…

When looking at JIS standards the Mizuno and Miura Giken are right on the edge of S20/S25C which makes complete sense as this is what they advertise and the Epon AF-Tour is right where it should be for S20C like Epon advertises.

The Scratch EZ-1 Iron also fell pretty close to being able to fit into the S25C category. The only surprise out all of these heads was the 1010 Scratch Wedge head. I will let you guy’s draw your on conclusions on the test results… Whatever the case I now know for a fact that of both Scratch Golf heads submitted for metallurgy testing none of them are 1018.

I requested the destroyed heads returned to us so we could take pictures. The results just got back to us today via Email we also have the data listed next to the picture of the club head via METL for those who want to question the test.

doesn’t surprise me at all.

Nice call Chris.

You got ’em by the ballz, buddy! Scratch had been LYING, flat out. Somebody at the BBB should ring them up. Well done. Really well done. I am very pleased to see these results. You have done a wonderful thing. Now lets see whether Scratch will cough it up and own up and man up.

Finally, you get to the bottom of this. Well done.

Thank you for standing up and getting to the bottom of this, when a manufacturer throws a BS out there, someone needs to call out on it. Get this word out quick, before you get bombarded by their lawyers… get a feeling Scratch will not take this like a man.

Does this mean that Mizuno is also misleading customers? As they advertise their irons as 1025 carbon steel rather than 1020…

Can I ask a simple question? Why did you decide to start this fight? Is your motive to ruin the company’s business? Why now? Just curious

You’ve raised interesting points, and I hope that the truth finally comes out. However, I really question your motives. Your points are getting lost in the anger and venom that you have spewed on some of the other message boards. Calling Scratch fans “nuthuggers” really reflects poorly on your message, your business, and you. This shows a certain amount of resentment, possibly because of their success? Disclosure: I do not play any Scratch clubs, nor do I consider myself a Scratch fanboy. I think Mizuno makes a better product.

Hi Garth, Here is the thing, Mizuno’s main selling point isnt S25C “the softest metal in all of golf” or Chuo Forged while Scratch always uses the same line of “1018 the softest metal in all of golf and Ishihara Forged”. none of which are true and publications are putting it into print. Also I think that for the most part Mizuno is spot on both S25C & S20C are what forged clubs are supposed to be made from. Other mizuno heads come out to .23 to .25 carbon which is inline with what they promote.

I don’t consider my first blog post starting a fight and here are the reasons… 1. It’s true, 2. Its a blog/my opinion and 3 this thing really grew legs when Ari came out in public and attacked me on a personal level. Only THEN we had a BIG problem because in my post I actually stuck to the points and praised him as an individual. He used attacking me on a personal level as his leg to stand on. If he was in the right he could stick to the facts and stay away from saying personal things that were untrue.

Hi Mike, I do think I am aggressive but again we were not the ones to go to personal attacks. My points and opinions have been clearly written. Ari has said things to mislead the consumer. Me stating that those who wish death upon me for uncovering the truth are nuthuggers is not really the point here, I could have chosen better words no doubt.

Many only want to pick sides instead of find out if they have been mislead.

If a brand is going to be out in the majority of public forums making claims and putting themselves out in front for all to see they should at the very least tell the truth.

1. Ishihara & Ishihara-Shoten doesn’t forge golf clubs

2. Mr. Ishihara (MOZ) passed on & Ari did in fact attempt to affiliate himself with MOZ on multiple occasions

3. The heads are indeed open model dispite Ari saying they are original. (only now he admits it)

4. Our TSG wedge was not 1018 Ishihara Forged and we marketed and sold it on those points.

5. Test results proove that their irons are right around 1025 not 1018 as advertised

On top of that the test results they posted don’t come out to 1018, they come out to 1015 or S25C.

What have I lied about?

on top of that you can catch him contridicting his own words saying that Scratch & Miura purchased their raw heads somewhere other than Ishihara. When I wrote the first blog Ari attacked me saying that what I said about Miura not forging their own heads in house was rediculous. Yet Ari was actually the first person to state this to the public back in 2006.

and their “we dont pay for play” statement…. Marketing they dont pay their players anything and when getting called on it adding the word’s “upfront”.

Most of their selling points were not true, you can say shady at best but in the end i made a blog post exposing it, When i was attacked, i hit back harder and held my ground. I offered to apologize, retract, and clear anything up if I was wrong.

If a company is gonna put themselves out there in the public’s eye to spread a message for profit and sales they beter make sure that message is honest and true.

Your Message WELL DONE IM GLAD U STOOD UP AND PUT THEM IN THEIR PLACE, I SHOULDVE KNOWN IVE BEEN USING THEIR CLUBS FR 2 YRS NOW AND I NEVER LIKED EM, THE WEDGE FELT CHEAP FR ONE THING,IT HAD NO CRISP FEEL AT ALL. THEIR IRONS NEVER HAD ANY RESPONSE TO EM, PLUS THEY MADE ME WAIT 3 FRIGIN MONTHS TO GET THEM WHAT A DAM JOKE THAT IS TO BEGIN WITH,THAT SHOULD HAVE TOLD ME SOMETHING RIGHT THERE NOT TO MENTION THE LENGTHS OF SHAFTS WERNT RIGHT. SO I WAITED 3 MONTHS FR CLUBS THAT WERNT EVEN THE RIGHT LENGTH .

In Ari’s tests from MSI the results don’t show 1018 they show 1015 or S15C. What’s odd is we have never heard the term “American 1018” used by Scratch.

S15C is JIS grade material so in those tests he may be using something of a higher quality than 1018. If that’s the case he should run with that because 1018 is a clear downgrade over S15C.

Then again this 1018 thing was just my hunch. Based on both Ari’s MSi test and our METL test still nothing came in at 1018 as Scratch advertises. That still doesn’t explain the 1010 rating we had in the METL test.

I still can’t find 1018 being offered by any foundry in Japan. It is highly unlikely that Scratch has been purchasing 1018 from the USA or China and shipping it to Japan because thats a huge extra expense they have to pay to use inferior metal.

Importing 1018 from the USA or China and using a middle company like Ishihara-Shoten would in theory add a lot to the products wholesale cost. Their margins are too good for that.

I doubt they were sourcing 1018 from the USA and shipping it to Japan when things first started. What would prove me wrong is severa past invoices dated from the American foundry showing that 1018 heads were shipped to the factory in Japan.

I can however find S15C in Japan similar to what Miura has used for wedges in the past. It’s about the same price as S25C and available from a couple of factories. It just so happens that one of the two factories that supply S15C is the same one that Ari claimed supplies Scratch & Miura back in 2006. Both of those factories do not supply 1018.

S15C is no longer used by wedge companies in Japan because the hardness rating becomes the same as S20C and S25C after heat treatment. S15C is able to be forged using lower heat and a less pressured press. Golf Engineers still do not suggest S15C for golf club use over S20C & S25C.

Ari’s MSi tests show 1015 or S15C not 1018. His own evidence goes against his claim of 1018.

I didn’t think the public would get held up on the 1018 thing as much as they did. I thought that Ishihara not being a foundry was the big deal.

Unfortunately your motives are to sell more products like any other retailer. Your “investigative reporting” is just another way to steer sheep to your selection of clubs.

“Scratch and Miura are telling lies, so buy an Epon from me.” Is that what you meant to say?

If you are so ethical and knowledgable, please do a thorough investigation into how Taylormade and other products you sell are manufactured. I will be very interested to see your story of how the Taylormade R9 Japanese version you sell for $700 is made right next to another brand that retails for $200.

@Brad:

Brad,

What the f**K is wrong with you? “your motives are to sell more products”. Nothing wrong with that. He got bills to pay as well. As least he does his homework and wants to inform others. My proshop just wants to push what he can sell.

He is not saying

“Scratch and Miura are telling lies, so buy an Epon from me”. You are. Cut this sh*t.

Why don’t u do something useful and run some tests against Taylormade. yeah I didn’t think so.

Well done Chris. What people are not catching here is this. the faithful to Scratch, and I don’t know why, will continue to play his product. Nothing wrong with that. All you did was to inform the consumer that the company is full of lies. Nothing wrong with that. Comendable on my part. What will be interesting here is reading Ari response. I got the same email he sent to you, I’ve submitted my clubs for testing in Chicago. Ill keep you posted. In the read between the lines, I have to work on a statement thusly stating how I was tricked by overseas manufacturers. They lied to me. Then he will issue an apology stating he product is this and will search for the best foundry to make his prduct.

That said, I did play his irons recently, and to be honest, they felt nice.

Would I game them, Sure…. Not for the price he is asking for. The problem I see here is this. One cant offer any constructive criticism to anyone w/o them breathing down a neck. Real class to those people. Like nothing is better than the product your playing. Here you are, Im sure there is better product than my 710MB, but for now, that is what I’m gmaing. however, the big issue here is I keep an open eye to a possibility of better equipment.

Just my 2 cents

So Scratch advertises using the “softest” steel in golf and you just confirmed it.

(actual 1010 vs 1018 claimed vs 1020 of others)

In fairness, I guess you also confirmed they use a cheaper, lower tolerance Chinese steel if we go by your knowledge of material supply in Japan (i have no reason to doubt you on this issue) . But if they source this material primarily for the feel and are comfortable with the quality control then I don’t see the problem. Its not like people are using their wedges to reinforce bridges or something.

Hi Chris, as you have stated in your previous blog post, this is actually a bigger news for Miura. So if you could confirm a few things.

A) Now you have stated pretty clearly that Miura do not forged their own club, are their clubs even their own original design at all? Or are they simply club heads forged by other foundary and they pick and choose which one to include in their line up?

B) If Miura’s simply purchasing heads from other foundary, then wouldn’t they have the huge margin much like what you’ve claim Scratch to have, since both company are charging quite heavty prices on their irons?

C) In your own opinion, say if Miura’s purchasing heads from other foundary, is it still posible that Miura’s club of superior quality due to their QC of tight tollerance? Or is that simply marketing?

I hope you can answer these questions for me….

From,

A stunned and disappointed Miura supporter

Hi Derek, Our head came out to 1010, their head came out to 1015. Where is the 1018? They advertise 1018 as the main selling point yet it was not the case. They market Ishihara Forged yet they dont forge. They market 1018 as the softest metal in golf which was not the case. 3 of the biggest marketing claims were untrue.

Hi D, Yes those molds belong to Miura, The process is Miura’s forging process. They just dont forge steps 1,2, & 3 themselves they only do step 4.

No Miura’s are their own molds also none of their heads are multi brand open models like Scratch uses. Miura’s molds are used only for the Miura brand.

What makes the tollerance so great with Miura is the spin welded hosel. You have a 2 piece head, the weigh the larger piece then find the hosel that weighs the perfect amount so that the head weight is spot on. That allows a final form of adjustment. With brands that use a 3-D one piece mold after the club is final pressed that head is that weight and they have to hand pick. Spin welded hosels have tighter specs.

On the down side of that it’s a 2 piece head meaning the design is often never the same as the original concept or mold. Say an OEM designs a head in CAD and all the CG and axis points are supposed to be in a certain area. Well with 2-D 2piece forgings these points are not as consistent and the overall design of the club is not exactly as intended.

Daniel,

Your wife cheated on you or something? man, take a pill. Everyone is trying to make a buck here and nobody is a saint here.

I have hit all manner of forged, cast, 1018, 1025, 8620, 431 and other clubs in my years of playing tournament golf. For the player, the bottom line is performance. Period! I don’t care if you hand me a wedge made of pure lead. If it performs and gives me an edge, I’ll put it in the bag.

I’m not sure what the motivation was in the beginning to denounce Scratch and Miura and their manufacturing processes. I’m pretty sure very very few players you give a wedge to can tell if it’s made of 1018 vs 1025 steel just by hitting shots. I can further assume that very very few players would notice a difference in performance between a 1018 and 1025 wedge.

The golfing public has been led to believe that playing with a forged wedge is highly desirable, yet most people never play with one! All Cleveland, and Titleist Vokey wedges for example are cast.

Let’s just forget about this stupid name calling and just play some golf eh?

Your Message Miura heads are part forged down the street from their foundry in another one and are made exactly the same as if it was in their foundry they make sure those heads are made exactly the way they do em then they inspect em and do the rest of final forging steps, SAME exact club that gys on tour are getting especially all the nike staffers.

@John Duval:

Hi John, Yes performance always matters most. You need to remember off the start I did not denounce Scratch or Miura, I simply stated that Miura was not forged in house and that in my opinion that Scratch isn’t using 1018. I have every right to state my opinion but more importantly the info I shared does indeed help the consumer understand Miura & Scratch product better. Just think before my post people were thought Miura is a foundry and scratch’s used 1018 or 1018 was the softest steel in golf or that Scratch is Ishihara forged. Well let the truth be known, its S15C in the wedges and approx. S25C in the irons unlike they advertise.

Your 100% right after 1018 or S15C is heat treated it’s the same feel as S25C. The HRB rating comes out to the same 70’s – 80.

Actually Forged golf product is still tops, You need to realize that in the states even the pro’s on the PGA tour are not playing the best PERFORMING or best quality built product. 90% of clubs in Japan are still forged.

@Ron:

Hi Ron, Your a bit wrong on that sir. Yes 2-D 2 piece is the process miura uses and requests from the foundry they purchase from, Kyoei used to use the same process as well. That same foundry produces 2-D 2 piece heads the same way for other customers they have as well like the spin welded heads scratch buy’s for their wedges.

Yes Miura does step#4 of their forging process in house. 1,2, & 3 are done at the actual foundry.

Your also misinformed about nike staffers using Miura product. If your talking about the split cavity from way back no staffers use that anymore. Nike blades are NOT produced by Miura nor are any of their other clubs.

Your Message@Ron:

I find all of this so interesting. I was looking for new clubs 5 months ago. While at the Angeles National Golf course range I meet a man who had just purchased a new set of Scratch Wedges. We struck up a conversation and he let me hit half a bucket with them as we compared them to my Mizuno wedges. I felt they performed reasonably well but attributed it to the fresh grooves. I admired the ferules with two distinct red stripes and the custom personalized stamping on the heads. The man told me who he had talked to at Scratch and what they had told him and about the deal they had made him including shipping. He said he had ordered them only a week ago and got them quickly because ( other than the personalized stampings ) the clubs were ‘in stock’. I had heard good things about Scratch so I called the next day to ask about the same deal. They said that they did not & never have had ferrules with two red stripes ( I had them email me photos of available ferrules and nothing close was shown ) they said that they could not honor the same price either, and that basically they were clueless as to what I saw at the range. The clubs I tried at the range were brand new. I closely examined them for over a half hour. I had taken the guys card too. So I was really baffled by Scratch’s response to me. It was like they were trying to get me off the subject at every chance during the conversation and talk me into having custom irons made. At the time it frustrated me but now it makes perfect sense as I think they had sold the guy something that had been laying around that they wanted to get rid of. Never did buy anything from them.

Any more news on this, Chris? There are way too many arseholes on GolfWRX, some of them the marshalls themselves who obviously spent some serious cash on buying bullshit equipment from Scratch. And there are way too many CHILDREN on GolfWRX, way too many teenagers and college kids who act like 6 year olds getting Xmas gifts. I mean if they were told they were getting a certain Xmas gift of a special thing they wanted only to find out that what they received was a knock-off fake, would they be happy? I don’t think so.

Your Message@idrive:

Please read and then consider posting this at your Scratch Test Results page. Why? You guys have evinced on that page little genuine knowledge about metallurgy. What is stated there does not get to the heart of the matter and must be confusing to the public. To the point, metallurgy theory states that the less carbon used in steel making the softer the steel. So, if you are looking for a very soft steel in a wedge, carbon content below 1018 is even better than 1018. That is, it is better for feel for dwell time (ball on face surface) and therefore better for control, especially in shaping shots and shot game distance. An elemental analysis of the different steel contents used by Scratch should not be compared to UNS or JIS standards — because those standards are to ensure safety in construction, whether it be buildings or highways or bridges and the alike. Here, you want less strength as a trade off for control. The fact is — with 1018 or 1010 — you will probably have to check the loft and lie angles every few months, so the clubs are high maintenance. Avoiding high maintenance is why Mizuno et al do not use such soft steel. Okay, your test actually show that Scratch is far softer and desirable than what they advertise.

@Robin:

Hi Robin,

Our post actually says that whatever the result proves to be anything would be an upgrade over actual 1018 steel. I always understood that those results would come back S15/S20/S25C based on what all Japanese factories offer to their customers.

1015, 1010 JIS costs exactly the same as S25C. 1015 is not considered equal to S25C for use in golf club production.

If the hardness rating is HRB77-80 in both materials it’s feel comes down to other design attributes in regards to soft feel.

In fact all brands have moved away from S15C. Miura stopped using it, Yururi stopped, anyone else using it ? When I request S15C they say its avaliable, the price is the same but they do not suggest it. A major reason why its not suggested is due to the amount of heat treating needed to get it to the proper HRB.

Here is the thing, This isnt just my opinion. I dont just come up with this stuff in my sleep. Common knowledge is 1018 doesnt come out of Japan, and S15C is not the optimal selection for a golf club material.

If a company is claiming 1018 and a test result comes out to 1010 that doesnt mean its S10C. It means that whatever metal they are using is so way off spec its carbon and other minerals fall into the 1010 category.

In regards to your comment about UNS or JIS… That comes into the picture becuase there is no 1018 JIS meaning IF scratch was honest about what their product was made of it would have to come from elsewhere.

In the end the result is very clear. Scratch doesnt use 1018 as advertised. Their clubs are not Forged by Ishihara as advertised. The irons are S25C while being advertised as 1018.

Hi, I respectfully disagree categorically to your post. Technically, every issue you list is debatable and you conclusions are speculative (too many unfounded assumptions), lack adequate scientific foundation (lack of metallurgical concept awareness) and substantial evidence (single sample size). Some of the information you list is plainly misplaced in your argument and irrelevant thereto. Consequently, you are defaming a company based on misinformation that you are publishing for some unknown reason. Bias of some kind? Other information from you website shows that you are not even qualified to have an opinion about engineering matters — are you a professor of engineering? Have you published any scientific studies on these matters? Do you have a curriculum vitae with substantial qualifications in this subject? In a court of law, your tests would not be admissible and you would not be qualified to testify — you would have to hire a real expert who can answer all the tough technical questions. Specifics: (1) if you wants truly supporting evidence — you need many samples from Scratch products so you have statistical validity, samples from several batches; (2) the fact that chromium shows up in your wedge sample shows the test may have been contaminated by surface plating material, which jeopardizes the validity of a core sample; (3) You don’t present the allowable variance or range of percentages that JIS or UNS allows in a given match of finished steel. You fail to present how the samples were obtained and whether such sample taking was the same method that JIS or UNS uses when it samples and certifies steel; (4) as to metallurgical theory you fail to comprehend how steel is an amalgam of iron and carbon, where the shearing strength, malleability, and plasticity vary greatly not only by percentage of carbon but also by how the carbon is variegated into the iron mass. There are various forms of variegation of carbon, such as rolled, grained, tempered, heat cured, cold cured — as well as dozens of doping compounds used to disperse the carbon evenly into the crystal structure or the iron. There’s also dozens of alloying elements used to boister the basic carbon anti-shearing force. And on and on… Metallurgy is actually a complex and compound science which takes a strong knowledge of both chemistry and engineering. Why? Because steel is not formed from chemical reactions but from a kind of manufacturing soup, so to speak. It’s therefore also a kind of art. You don’t know the outcome until you test the amalgam you tried to make. The intense heat and safety issues make manufacture of steel an often hit or miss process — this goes especially to the issue you have of using a single sample. In the world of steel, such a sample is irrelevant simply because manufacturing process is so volatile. So, you can’t claim 1010 is way off spec for 1018 without a full blown valid set of tests using exact UNS and/or JIS test methods under strict quality controls. Further, even if such a broad based test showed that Scratch routinely used 0.10% carbon, that does not mean the wedge is defective. You have to look further at how the carbon is distributed in the iron matrix, how the steel was cured, how the grain was obtained — microscopic studies are used to look at whether the carbon is evenly distributed and/or distributed in a pattern that yields optimum shearing strength and malleability for the intended application. Again, if your application is for soft metal that can tolerate 100 mph impacts of a 3 oz. rubber ball — that is one thing to test for. If you want soft metal that will not shatter during a point 10 earth quake, that is another matter. You need to work out the balance between the ability of the steel to give versus it’s strength. Some modern architects design a lamination of high carbon brittle steel next to low carbon flexible steel in earth quake prevention designs. Lastly, Don’t take any of this personally, there are bookshelves of studies on steel making and two centuries of industrial trials and patents. Which all militates to state that you just cannot validity lay claim to a persuasive conclusion about Scratch wedges with so little evidence or knowledge of what is going on. In fact, you didn’t even include a practical test of the some objective golf challenge in your evaluation. You just assumed that soft steel no value at a rating below what the big names use. QED.

Hi Robin,

Actually we did specify these are UNS results not JIS. Your arguement does nothing to help scratch. We tested 3 clubs all were not what were advertised. THEN Scratch did their own tests and none showed 1018 as they advertise. So how are you going to argue against that?

How are you going to argue against the fact that no foundries offer 1018 in Japan? Even the one that actually supplies scratch.

I may not be a metallurgy expert but you are not a club making engineer. Considering your no expert on the use of different metals in golf clubs I will have to take the word of Actual material suppliers, foundries, and engineers.

Wouldnt you agree? Just as I wouldnt ask a homless person for advice on real estate, I wouldnt ask you about the use of various metals in golf clubs. Reason why there is no weight in your arguement is because you simply question the process.

Furthermore you go into microscopic testing, thats exactly what the two testing companies did to come to the conclusion that its not 1018.

You say its neccesarry to get into malleability and plasticity for use in golf clubs. Thats funny. Your mention of Chromium and your conclusion that the plating contaminated the result is silly because that didn’t explain the chromium content in the raw head ( no finish ) submitted.

Please let me make this simple for you…

1. Both Scratch and Our results prove they are not using 1018 as advertised.

2. Scratch has mislead the public to think that the product is Ishihara Forged when they dont forge golf clubs

3. Scratch claims that their irons are 1018 when they are proven to be 1025

4. Scratch used to claim their irons are original design until that truth was revealed

You see the trend?

You want a bigger test taken when the results of both sides show via two different and VERY credible metal testing companies came back showing the result was NOT 1018.

You dont find it odd that I was right before the test was even taken? We dont need heavy testing when the foundry they purchase raw blanks from has confirmed they dont offer 1018.

In regards to golf club manufacturing the TRUTH is an UPGRADE over the LIE. S25C in irons is better than 1018 in irons, S15C/S20C/S25C in wedges is superior to 1018.

Well, I had to see for myself and when I visited Scratch YESTERDAY, Jeff McCoy had original drawings and the original ground heads that he did to make their molds. They told me what I thought I knew about you. They wouldn’t increase your margin, so you attacked them. Kind of petty. They are currently working to get all casting and forging done in the USA regardless of their increase in cost so they can control quality and timing of shipments. Also found out the 2 of the largest OEM’s in the world forge and cast at the same facilities that they use in China and Japan. I would say calling all of their designs un original is kind of a joke. That is like saying Scotty Cameron made the first putter design. Can anyone say “nice job on that detour, futura putter scotty.

Your Message@Funny:

1. Their Irons are Open Model. Having Drawings or raw ground heads means nothing. The AR-1, EX-1 and their blade are all adjusted pre made designs. over a dozen brands have used these heads. Do you think its just coincedence they all designed the same thing?

2. Scratch had GREAT margins! Much better than 95% of the brands we sell today. I had no gripe with the prices. Ask U.S retail stores, the margins are good!

3. FYI the two largest OEMs in the world produce the majority of clubs in china. If your looking at pure parent company size the two largest OEMs are Japanese.

Nothing against you man, but they are just trying to confuse you. Of course they want to cover the BS they spread. Their wedges are S15C, the Irons are S25C. They advertise 1018. Do some digging and research on your own.

I understand you would like them because they are nice people and friendly vs me being confrontational and direct but bottom line is that they have been misleading the consumer.

Good thing I play Hogans, Apex 50s, Ft. Worth forged and buttery soft. Did slip on some Nippons and these rock.

I do not really mind if Scratch uses 1025 instead of 1018. All I care is that they are forged well and most importantly forged IN Japan. If these two requirements are met, I’d be interested in obtaining a set. Am I still allowed to be interested?

It’s most likely 1015 in the wedges and 1025 in the irons. If I were the one in charge of your life I would indeed allow you to be interested!

But are they forged in japan? And forged well for that matter?

@Your Name:

Yes forged in Japan of quality forgings.

Hey TSG!….what is the dirt on Geotech and their findings…..??Your Message@TourSpecGolfer:

@TourSpecGolfer:

No dirt, They claim S25C made in Japan for their Japanese forgings and that’s exactly what the test results show.

This is an awesome post!!!!! WAR SCRATCH!!!!

BEST FORGED IRONS HANDS DOWN ARE KZG

After reading threads from my golf spy really make me sick… I believe TSG had produced evidence right?… they then played it down and changed the topic into how nice Ari is or how open Bill is etc etc.. and what TSG should have done before making such a post etc.. all these are BS. They downplayed and detoured from the main issue after the results were shown.

Scratch’s independent test result? well if scratch really think that their result is correct one, Inferences can be drawn on why there was no legal suit by Scratch or Miura (i love miura btw, i’m just stating out the facts) filed in court against TSG for defamation? and claim that TSG’s result is wrong, flawed or even concocted?

One can only conclude that they have no case at all against TSG.

I have nothing to gain here, i’ve never bought anything from TSG, i don’t even use Scratch, I’m merely a consumer who hates to be misrepresented. I know some of you may think that scratch’s wedges, or irons feels great and work for you but hey, you expect me to pay a premium for cheap stuff, thats like buying a lamborghini with a Hyundai Engine (and they tell you its a 5.5 litre larmborghini engine). Tell me if you won’t get mad at all…

Your Message@Rod:

No need to hate Sir. You sound like the people you hate on GolfWRX.

@TSG

If you are trying to expose the golf industries manufacturing processes why not do a complete gutting. Why call out 2 of the smallest companies in the business? Why not go after everyone?

If you need to pick on anyone in the golf industry go after the putter manufacturers. I mean the ones that charge 1k and up for 1 club. Seriously!!!

I understand the discrepancy between what is true and what has been advertised getting on the nerves of those who are in direct competition with one another. What I find puzzling, are the number of people actually focusing on this. 90 out of 100 golfers will never (honestly) break 100, and those who do (including touring pro’s) wouldn’t be able to tell the difference between 1018 or 1020 or 1025 steel by the performance of the club. You had to have an independent metal lab perform tests like NASA would to find the differences, you think your 20 handicapper is gonna notice? I read many of the comments subsequent to the test and I think many of those individuals would have spent their time more effectively at the range. The deficits in your game are truly NOT due to your lack of due diligence when selecting a club….they are due to your game, or lack thereof.

I think this is an interesting article. Whether you feel like you did or not, you did wage a war when you dig into someone’s materials like you did. You have every right to, don’t get me wrong. But I feel as though you miss the point when it comes to a company like Scratch. See, I come from the bike business and in our business the big names all have “high-end” (high-cost) carbon “race” frames produced in Asia. They are great bikes, don’t get me wrong but they often times use a lower quality grade of carbon fiber and re-name it something proprietary to make it sound nicer than it actually is. Truth is, the product is engineered to use the lesser materials to their highest performance applications. Is there anything wrong with that? No, not if you want yo pay to play. In our industry though, there are small handbuilders that build custom and semi-custom steel, titanium or carbon frames. They cost a lot, hell yeah, but they aren’t making ridiculous claims. They will says, we use Reynolds or Dedaccai or Columbus steel. We don’t ask what grade of steel because they are the professionals and they are making us a hand-crafted piece of equipment. To me, that’s what Scratch is doing whether they are using 1020 or 1018 steel. I took a look at some of the brands you sell and it seems like you like the high-cost variation of in this anology. How different can one steel bike frame next to another be? the difference is in the metal that went in to making it, not the metal they used to make it. It’s the grit of the craftsman. Let’s be honest, not much has changed in iron designs over the course of a hundred years. Sure, tungsten plugs and larger sizes and plastic sticky thingys inside the cavity. Hell, I’m still playing an 8 year old set of Nike forged irons and a Nike driver that’s older than that! Could I tell you if they are 1018 or 1020 or 1025? Fuck now. But I can still tell you when I put a good swing on one.

I’d quit waging wars. Ari might have come down on you hard but you have to be ready for a black eye when you show up to a party planning to fight.

Cheers.

Also, sorry to dig up an old thread. Ha!

Hi Mark,

Let me ask you a simple question: Do you think they produce a high quality product in terms of Grind, Fit, & Finish?

We are not competitors and If someone wants to buy 10 year old open model heads with their logo on it for over 1k go right ahead.

Here’s a quote from their website:

Scratch AR-1 irons are forged from 1018 carbon steel, the softest material utilized by any manufacturer. After the initial forging process, our raw heads are ground and finished completely by hand. The end result is the finest hand made forged traditional cavity back iron in golf.

Really? I call bullshit 3 times in 1 paragraph. If you buy into this then you need to go out and purchase a set of their clubs immediately and tell everyone you have the softest and best golf clubs in the world.

If you think Iron heads have not advanced significantly in even the last 10 years I can’t even talk to you until you get caught up on what’s been going on.

Hello Chris ( TSG ),

I am very impressed with your company and the candid information on the website. It is very refreshing to witness honesty and true pride in manufacturing !

My brief qiestion is:

What distributors or dealers carry highly engineered and presision forged irons and woods within the U.S, ?

It seems that all of the U.S. “RECREATIONAL FOUNDRIES” have outsourced to much inferior and poorly “quality controlled”, recreational equipment manufacturers, where the spec tolerance is more volatile than wall street on MONDAYS.

When you have time, I’d greatly appreciate any thoughts/ feedback. Thank you kindly.

-D BROWN

Great analysis Chris. Would the fact that the wedge came up as 1010 carbon result in it potentially wearing faster? I have a few Scratch 1018 wedges and they all wear much faster than other forged wedges I have played. My most recent was the first of their conforming groove wedges and it was completely worn through and started browning after a few months. I only had about 8-10 rounds with it and maybe 50 practice shots.