There are a plethora of high end golf shafts to choose from in Japan as the top shaft makers here are always introducing new models and OEM’s don’t hesitate to offer them as upgrades from the factory. Japanese performance shafts are NOT cheap, but the fact is there is demand and a market for them as the Japanese love to tinker and toy with their clubs and the market here really is blown out of whack sometimes when it comes to the cost and amount of money players are willing to spend. Golf Digest Japan recently took a sampling of golfers and asked them why they decided to reshaft their drivers and the results are in the chart below which I originally posted on our brother blog Inpakuto.com:

Japanese golfers truly believe the shaft is the engine of the golf club. Getting the right shaft can mean magic and the wrong shaft can mean disaster. Many of the shaft brands have worked hard to capture the “tuning” market in Japan and this has forced brands to make better and better shafts and more and more choice in this fierce segment of golf gear. All this equals more choice for the consumer which is a great thing. Japanese golfers are ready to spend the money.

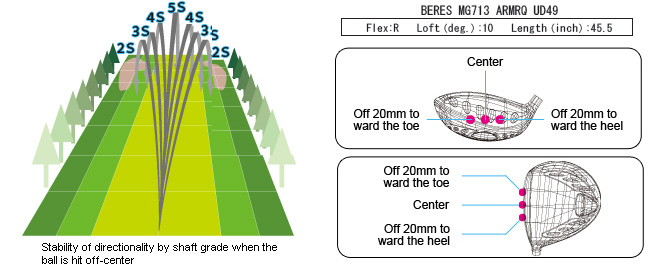

Besides changes in technology and new manufacturing processes, there has been an increase lately in use of higher end carbon in this up and coming premium shaft market. Honma Golf was one of the pioneers in offering models of shafts with different grade carbon, the Honma 5 Star rating system. Honma enthusiasts are well aware of this system where the more stars a shaft has, means the higher the grade and density of carbon used for that shaft. You can see in the table below the difference in dispersion with off center hits and different grade Honma shafts. 5 Star being the highest and 2 star the lowest.

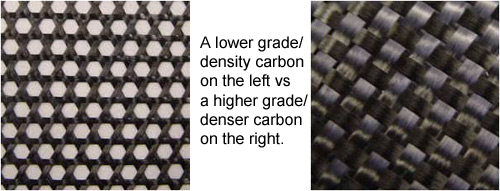

So how does carbon grading work? Shafts are created with carbon fibers weaved together, and these fibers are measured by their modulus of elasticity in tension. Typical golf shafts are around 24t or 30t, the measurement of tensile strength. These grade shafts are more flexible and because of this the shaft is slow to regain its original shape on the downswing creating inconsistent impact where a player must rely heavily on timing due to the flexibility of the shaft. As the tensile strength increases the carbon weaves are more dense, more rigid and return more quickly to their original shape.

The flex and rebound of the shaft becomes more predictable equaling more consistent shots and much tighter dispersion. The higher tensile ratings ratings in golf shafts also are related to the higher grades containing more glass and metal particles which are more rigid and lower grades containing more flexible rubber particles.

Besides Honma Golf, Japan has seen high end shafts with ratings as high as 80t from shaft makers like Axiv, Crazy and Quadra. Most recently top Japanese shaft maker and a brand known worldwide to golfers, Fujikura Shaft released its new Rombax BangVoo in collaboration with golf boutique Muziik. This is the latest player in Japan’s Premium shaft market.

Besides Honma Golf, Japan has seen high end shafts with ratings as high as 80t from shaft makers like Axiv, Crazy and Quadra. Most recently top Japanese shaft maker and a brand known worldwide to golfers, Fujikura Shaft released its new Rombax BangVoo in collaboration with golf boutique Muziik. This is the latest player in Japan’s Premium shaft market.

The BangVoo shaft core uses high modulus triple axis weave 70t rated carbon with high focus on accuracy and explosive distance. Because of its 70t carbon, the BangVoo is predictable, golfers can trust their swing and know that when the BangVoo unloads the head will be right there at impact. Golfers do not need to worry about timing with the BangVoo as it has minimal energy loss and twisting , accelerating on the downswing to create amazing ball speeds at impact. A more accurate shaft equals more distance overall because a player will be in the fairway more often then not.

Besides BangVoo’s performance strengths, another thing the more rigid high quality carbon brings to the table is true flex. Fujikura has released the BangVoo with CPM ratings which they don’t usually do with their other models. Specs have Regular flex being 240cpm and two stiff models being 250 (S2 or SR) and 260cpm (S) and a true X-Flex at 270cpm. This premium shaft comes with a premium price tag at retail of just over $1000.00 but surely because of its price it will sell out in Japan.

I had a 240cpm Regular flex sent to me for which you see the pictures I took here. The 240cpm appears to be accurate for a finished club at 45″. We just put the shaft in a driver head finished at 45.75″ D1.8 and cpm came out to 233cpm at the longer length. Once I do more testing I will talk more about this setup and results. I can’t wait to try a $1000.00 shaft. (^_^)

I guess if people have the money why not buy the highest quality shaft there is? But for the regular joe like me I’m happy enough with the Tour AD and Diamanas you guys offer at more down to earth prices.

I’m guessing that the bangvoo would be similiar to honma’s 4 or 5 star shaft which are very pricey but made from the absolute best graphite composite materials. My father who travels to asia for business has a honma driver with a 4 star shaft, which launches straight drives when struck on the sweet spot, but draws ever so slightly when I mis-hit it, which is usually off the toe. I myself, have the fubuki alpha which is a wonderful shaft but “only” has 50t which is good enough for me. If I had 800 dollars to spend, I would get the mitsubish stinger prototype which I have tried and is similar to the alpha, but is made with boron(not new technology btw, honma has been making boron shafts for a long time which my father has in his honma irons). .

Actually the Bangvoo and shafts like Quadra and Crazy are made from even higher grade carbon than the 4 and 5 star Honma. Honma 4 Star is 46 x 50t carbon while 5 star is 50 x 50t. Bangvoo is 70t and Quadra and Crazy are 80t for their top shafts.