Yesterday I was in Tokyo to visit Gold’s Factory to talk to Master Sasaya about some future putters and how things in general are going. Gold’s is very busy with a queue of jobs from all around the world and as usually many beautiful putters are being produced and modified. Instead of doing a usual long write up, I thought I would make this more of a photoblog since I snapped some photos while I was there. Pictures can tell a whole story so I will just add a few lines here and there.

Before heading over to Nakajyuku in Itabashi, I thought I would swing by Shinjuku and check out some cameras. I brought along my Fuji X-Pro1 which I use for all my photos on this blog along with a 35mm f1.4 and a 18-55mm zoom. All the photos at Gold’s are with the 35mm and the outside shots the zoom lens.

I fiddled with a bunch of cameras including the Nikon D800, D600, Canon 5D MKIII, 6D, Leica M9, Sony a99 and RX-1 but in the end I decided my X-Pro1 didn’t really need updating.

Elections are coming up and just outside Shinjuku station I was surprised to find Yamamoto Taro an actor and celebrity campaigning for votes to commuters outside the station. He is actively involved with the anti-nuclear movement here in Japan especially after what happened with the Fukushima nuclear plant disaster.

I arrived in Nakajuku, a suburb in the Itabashi area of Tokyo which is home to Gold’s Factory.

As always Master Sasaya has his signature black tee on! After talking about different putters in production. I got the chance to watch him do his next generation premium zone milling for a customer of ours in Thailand.

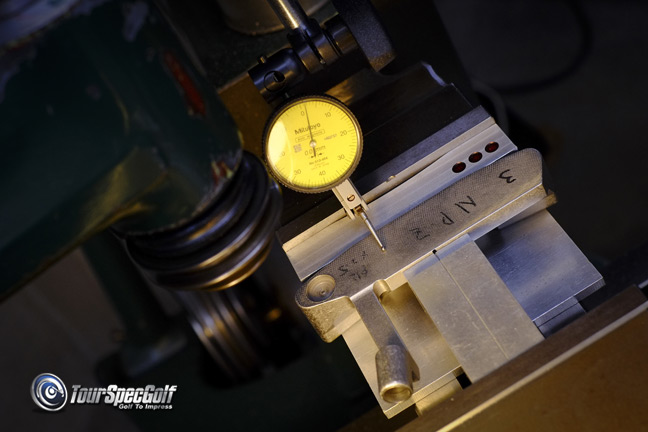

The first thing Master Sasaya does with all putters including those he manufactures as well as other brands he modifies is to make sure the face is perfectly flat. You would be surprised to find out how many big name putters do NOT have flat faces at which point Gold’s has has to mill the face flat first before milling grooves.

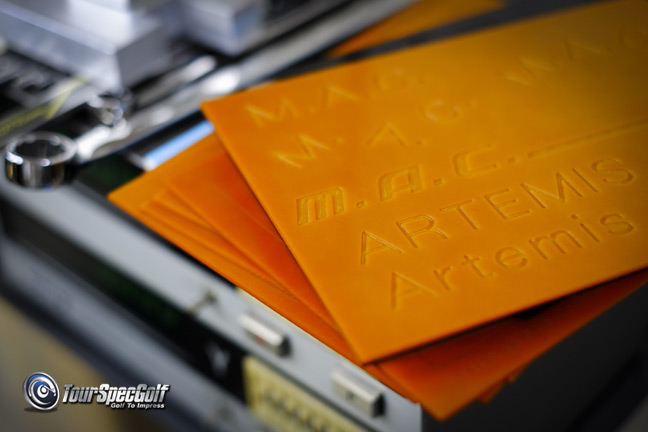

Master Sasaya mills all his putters by hand using templates that he created. This includes engraving of logos and words as well as you see in the orange template above.

I also tried to make a video of the milling process, some of you may have already seen some of the process in Tourspecgolfer’s Gold’s interview video. I shot this with the X-Pro1, in full manual, manual focus and handheld… hence quite shaky and out of focus!

And here is the finished milled face. Carefully done it takes about 1.5 hours to 2.0 hours. I’ve tot lots of photos so will post many more below here. Customers of ours may recognize their putters being made!

A special center shaft del mar style putter made for the president of DWD!

Machining putters aside, Gold’s knows that a putter has to be properly spec’ed and assembled. Special care is taken even installing the grip and checking the face angle of the heads.

A new short neck anser style putter. A beautiful blue accents GF00A for one of our customers in China. A couple of modified Scotty Camerons at the bottom.

After Tourspecgolfer’s Odyssey putter was modified to use a SUs303 face insert, replacing Odyssey inserts have been very hot at Gold’s. Gold’s uses a dual layer insert, an inner layer of aluminum and an outer later of JIS SUS303 machined with PZ Milling. The reason why they use aluminum as well is to keep the weight down. Adding just the SUS303 insert would be too much of an increase over the original feather light Odyssey insert. More shop photos below!

Overall it was another fun day at Gold’s Factory. Just a reminder that if you are having a putter made at Gold’s or have had one made in the past, you have the option of visiting Gold’s Factory if you come to Tokyo. Just contact us and let us know!

Great photography of some beautiful equipment. If money were no object I would buy several clubs and accessories on the site.