It’s been a while since I have dropped by Gold’s Factory and in the mean time, Gold’s has grown more popular than ever, especially here in Japan where their brand has received major publicity in most major golf magazines. Being featured in Golf Digest Japan, Alba, Even Golf, Waggle as well as top enthusiast magazine Choice, has really enhanced Gold’s Factory and Master Sasaya’s reputation as savvy putter and wedge creator and modifier. So when Sasaya-san contacted me last week asking me to drop by to talk about his new wedge and to grind a set based on my feedback I was very happy to oblige.

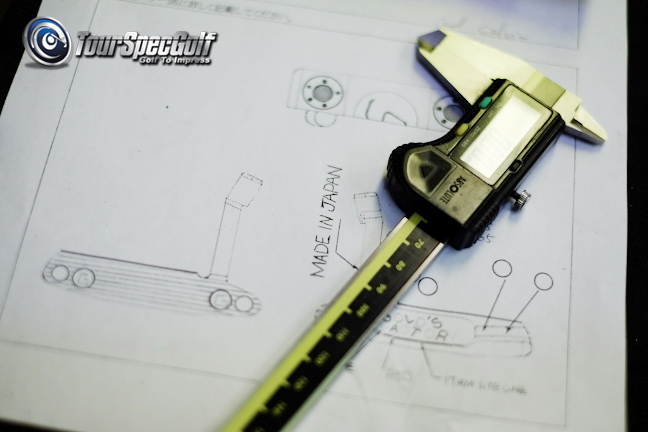

As you all know I get to take lots of pictures and test golf clubs mostly at home here in Kiminomori so it was nice to be able to pack up the camera and head out to Tokyo to shoot some pictures in a work shop rather than my backyard or at the range/golf course. I arrived at Gold’s Factory located deep in the heart of Nakajuku in Itabashi just after 10am and right away Sasaya-san pulled out a box of raw forged heads to show me. We talked a bit about wedge manufacturing and how a hand grind wedge from Gold’s Factory differs from a mass produced wedge which most mainstream brands produce. Sasaya-san explained to me this new hand grind wedge is forged from JIS SS400 in Himeji and is now being produced by Gold’s Factory with CNC machined conforming R&A grooves. For those not familiar with SS400, its equivalent hardness is about S18C. Raw heads are delivered at heavy 338g weights allowing for major customized grinding to each customer specifications. The new hand grind wedge also features a very fine CNC machined face milling, this milling can be varied from fine to deep.

Unlike mass produced wedges many of which are rolled in a barrel, Gold’s Factory grinds and sands and polishes from start to finish. They do send the wedge off for plating if that is required by the customer otherwise they finish the raw wedges themselves. The hand grind process is a tedious one but even before that, the planning of the wedges design must be considered. Sasaya-san and I talked about differences between preferred shapes and styles of wedges from Japanese golfers to American or overseas golfers. In Japan, many golfers prefer wider soles and more bounce due to the lusher and softer courses and bunkers. As Sasaya-san put it, the big round head with goose neck was made popular by Jumbo Ozaki and it has stuck. I told him this is not the wedge TSG customers overseas really want and he agreed that this was probably the case.

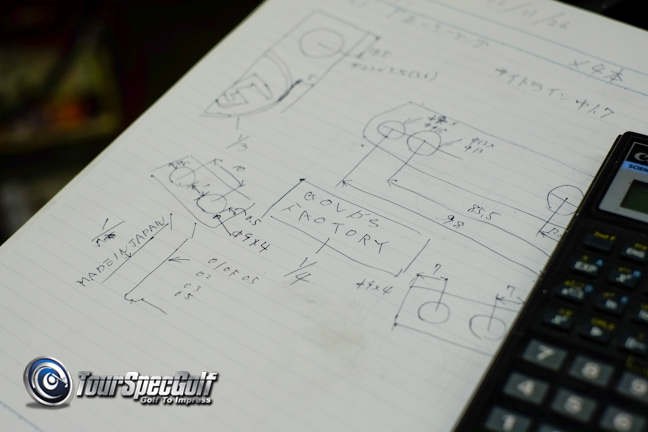

Breaking the wedge into various sections, we talked about the sole grind, the neck, including the back of the neck and how it flows to the top line as well as the front of the neck and how it flows to the leading edge. The neck is a sensitive part of the wedge and even the inner neck, or curve connecting the neck to the face and scorelines must be considered. A artfully ground neck will allow for the lines of the head to flow and for the design to balance. We talked about the top line as well as the head shape and leading edge and Sasaya-san explained he typically grinds the leading edge last in order to have it flow with the neck.

Based on popular feedback from customers I suggested to Sasaya-san we do an M style grind as its versatile and while not ultra thin it gives the appearance of a thinner sole. The trailing edge relief as well as the toe and heel relief allow for versatility in various lies and conditions and not to mention it looks good. (^_^)

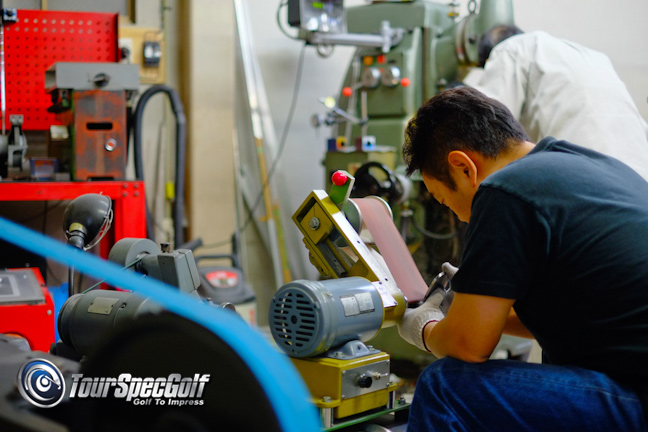

Most better players and TSG Customers seem to prefer less offset or a very straight neck so I requested this from Sasaya-san. He explained this would be the first thing he grind as its quite a bit of work to get the neck very straight and flat all around so that it flows into the blade of the wedge. In order to get that very straight neck, Sasaya-san spent quite some time grinding the neck portion by portion and closely inspecting its “lines” throughout the process.

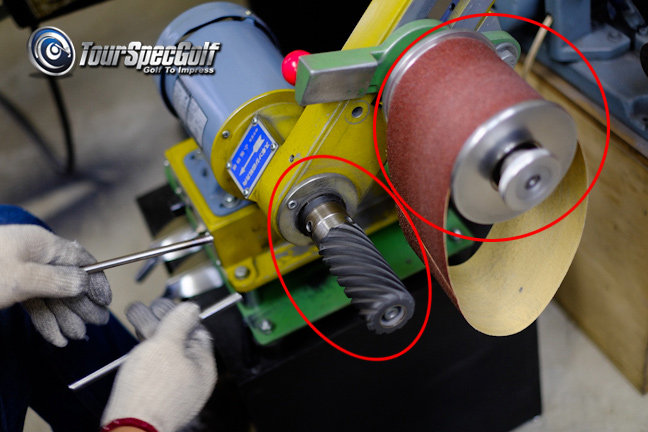

Next Sasaya-san moved to the sole. He has done the M grind quite a few times and quickly shaped the sole grind matching the trailing edge relief to flow into the straight neck. The heel relief will also allow the player to open up the wedge more easily and still point the leading edge at the target and keep it close to the ground for better contact. The initial grinding is actually the easy part and as an experienced master grinder, Sasaya-san can shape the wedge quite quickly. Its the fine tuning of the shape on the sand belt and much tighter parts like the curved inner neck that take more care. In the above picture you see the unfinished raw inner curve of the wedge and how close it comes to the face.

Many grinders grind/sand this curved portion in an up and down motion from top to bottom. Sasaya-sasn grinds the curve from neck towards the face without touching the face or scorlines. The sander is actually the most essential and most used tool in shaping and finishing the wedge even more so than the grinder which is used to get the general shape.

The sander uses different sized pins in order to reach and grind different areas of the wedge and Sasaya-san goes through a very labor intensive hand polishing using 60 grit sand paper all the way up to very fine 1000 grit for a perfectly smooth finish. This hand process takes hours and is part of the reason why the wedges cost so much but because of this process you can be ensured a perfectly shaped and flat wedge unlike mass produced wedges today which can lack consistency.

After grinding the neck and sole Sasaya-san moved on to the top line and shape of the head. We talked about how a company like Fourteen does a tapered top line and decided instead to do just a clean and simple thinner topline which gives it a nice blade like appearance at address.

We were getting closer to the desired shape of the head but I had one request for Sasaya-san and that was grind the heel side of the wedge lower so that the shape would be much more tear drop. This also gives the illusion of a higher toe and promotes working the ball diagonally across the length of the face for added spin control.

Finally Sasaya-san grinded and sanded the leading edge to match and flow into the neck. The straighter leading edge and the additional grinding I requested not only gave the wedge a very much tear drop shape but made the neck appear even straighter with the top line towards the heel being lower. It had pretty much taken the morning to create this shape which is still nowhere near done, additional touching up as well as lots of fine sanding is still required. At this point the heads were still around 314g in weight, so plenty of room for Sasasya-san to smooth out its looks and finish.

I decided that we would plate this wedge to prevent rusting and finish the wedge in a soft black with 1 dot indicating the AW and 2 dots indicating the SW to to keep the sole clean and the wedge simple. In a couple of weeks I should have the finished 52 and 58* set for pictures and they will look awesome. The Hand Grind wedge is still a custom made wedge like no other in Japan. Its the only wedge available here where you can dictate all the design aspects from the original raw head to finished product. There are also a ton of finishes including raw, raw polished, raw with gun blue, raw black, or plated finishes like chrome, chrome satin, white chrome (pearl satin like), Teflon black, Soft Black, Soft Black Mirror, Copper, Black Boron etc. Top that off with any engraving you want including custom logos and names all hand milled and you have your one of a kind wedge! Stay tuned for pics of the finished set and if anyone wants to make their own please feel free to contact us!

While I was there I also snapped pics of the Gold’s Factory workshop for your viewing pleasure!

Is there a ‘Jumbo Ozaki grind’ so to speak? I know GMA sells there wedges as such.

Not an actual grind but more the shape he made popular with many players back in his hey day. Is GMA still around? I don’t hear about it much these days…

I presume so. Not that I’ve ever actually seen a GMA club in a golf shop. The only place I’ve ever seen them is when I followed Jumbo round the Chunichi Crowns a couple of years ago.

is there still Golds Factory Flatback Prototype irons for sale?

How much are the wedges and what is the wait time on these

please advise

regards

Aj

flat backs sold out a long long time ago.

Wait is about 3 weeks per wedge set. Cost is in the pro shop.